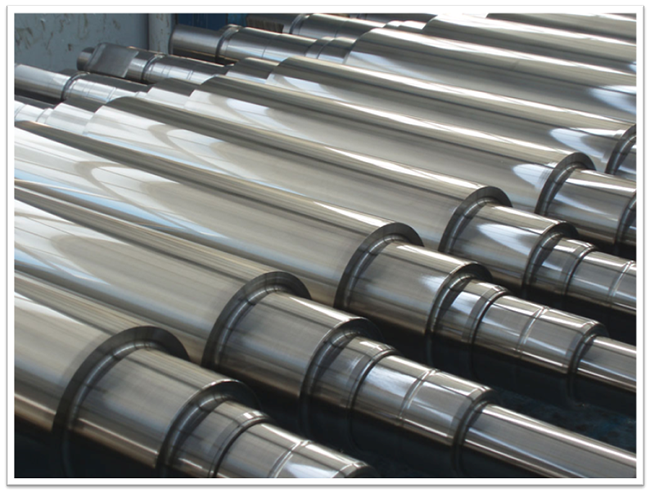

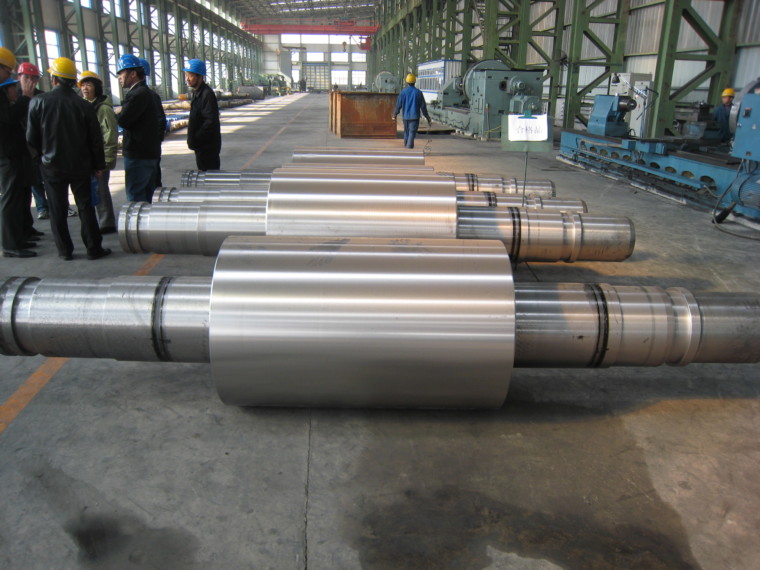

Cold Mill Rolls

Discover Our Cold Mill Roll Solutions

MBI Rolls provides precision-engineered rolls for cold rolling applications, where dimensional accuracy, smooth finishes, and surface quality are critical. Cold mills operate under high pressure and tight tolerances — and our rolls are built to meet those exacting demands.

Sourced from ISO 9001-certified partners, our cold mill rolls are designed for wear resistance, hardness stability, and consistent microstructure. Whether you’re producing automotive steel, appliance-grade strip, or specialty alloys, we supply the right rolls for the job.

- Superior surface finish and roundness retention

- Induction hardening and fine microstructure available

- Ideal for tandem, temper, and skin pass mills

- Final inspections conducted by MBI for quality assurance

| MILL TYPE | ROLL FUNCTION | MATERIAL | HARDNESS (Shore C) |

|---|---|---|---|

| Cold Rolling Mill | Intermediate Roll | 9Cr2M, MC3, MC5 | 70 ~ 85 HSD |

| Work Roll | 9Cr2MoR, 86CrMoV7, MC3, MC5 | 80 ~ 105 HSC | |

| Back-Up Roll | 60Cr3Mo, 9Cr2Mo, 86CrMoV7, 70Cr3NiMo | 60 ~ 80 HSC | |

| Sendzimir & Cluster Mill | Intermediate Roll | 5H12 | 55 ~ 60 HSC |

| Work Roll | Cr12Mo1V1, Cr12MoVCo | 60 ~ 65 HSC | |

| Forged Shaft | 42CrMo, 36CrNiMo4 | 35 ~ 45 HSC |

Not Sure What Roll You Need?

Our team will work with you to recommend the right roll for your position, product, and operating conditions — all backed by responsive service and long-term supplier relationships.